Open-Source System on Module

Open-source system on module (SoM) is a compact hardware solution providing core functions like processing and memory. Unlike standard SoMs, it allows full access to modify hardware and software, offering flexibility for custom applications. Supported by Android, Ubuntu, and Buildroot, open-source SoMs enable faster development and customization.

With Neardi’s open-source SoMs, customers can access 2D/3D drawings, firmware, and source code, supported by forums and technical assistance. This makes it easy to integrate and modify for any project, backed by both software and hardware support.

- Firmware: Ready-to-use firmware for fast integration.

- 2D/3D Drawings: Access to design schematics for complete customization.

WE OFFER

- Source Code: Open access to software code for easy modifications.

- Development Tools: A range of tools to help you program, debug, and optimize your product.

What is the Neardi Support Like for Open-Source SoMs?

Whether you need help with design modifications or software integration, Neardi offers comprehensive support to ensure a smooth development process.

Forum Support

A community-driven platform for sharing knowledge and solving problems.

Technical Support

Dedicated hardware and software technical assistance from our expert team

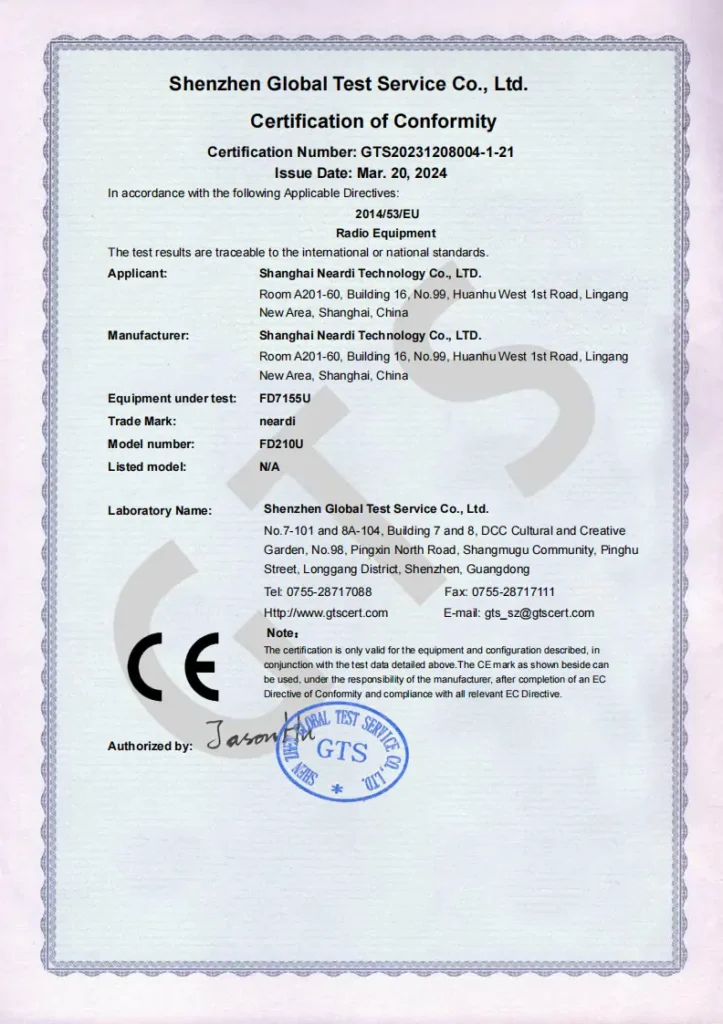

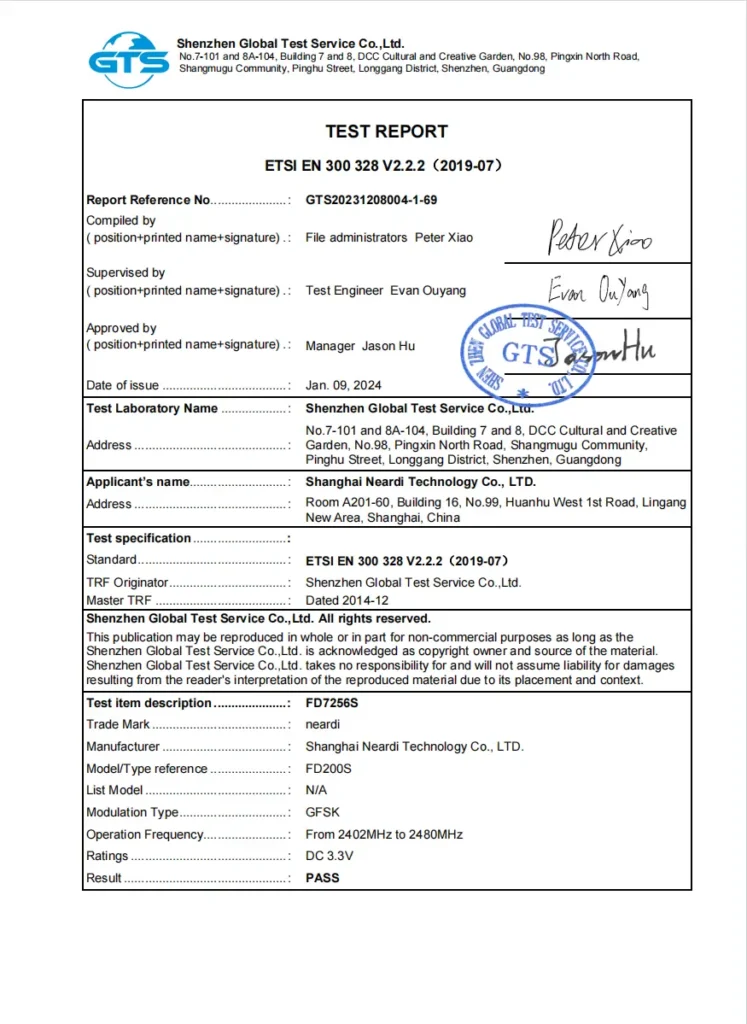

Certificates

Neardi Equipment

AOI Machine

AOI machine ensures quality control by detecting defects in Neardi's embedded boards and modules during production. It integrates seamlessly into the manufacturing process, verifying component accuracy and solder quality, ensuring reliable and high-performance products for customers.

Auto Printing Press Machine

Auto Printing Press Machine automates the process of printing patterns or texts onto surfaces like PCBs, reducing manual labor. Integrated into Neardi's production, it ensures precise labeling, component marking, or branding on boards, enhancing production efficiency and product traceability.

BGA Rework Station

BGA Rework Station is used to repair or replace Ball Grid Array (BGA) components on PCBs. Neardi's production, ensures accurate rework of complex components, enabling high-quality repairs and minimizing waste, ensuring the reliability of embedded boards and modules.

Lead-free Wave Solding Machine

Lead-free Wave Soldering Machine automates the soldering of electronic components to PCBs using a lead-free solder. In Neardi's production, it ensures precise, eco-friendly soldering for high-quality embedded boards, meeting environmental standards while enhancing product durability and performance.

Pick-and-place Machine

Pick-and-Place Machine automates the precise placement of electronic components onto PCBs. In Neardi's production process, it ensures fast, accurate assembly of embedded boards, enhancing manufacturing efficiency and product consistency while reducing errors in component placement.

Precise Hot Air Oven

Precise Hot Air Oven is used for controlled heating, curing, or drying of materials in electronics production. In Neardi's process, it ensures consistent curing of coatings or solder, optimizing the reliability and performance of embedded boards by providing uniform heat distribution during manufacturing.

Reflow Soldring Machine

Reflow Soldering Machine melts and solidifies solder paste to permanently attach surface-mounted components to PCBs. In Neardi's production, it ensures precise and uniform soldering of embedded boards, enhancing connection reliability and maintaining high-quality standards for electronic products.

SPI Machine

SPI (Solder Paste Inspection) Machine checks the accuracy of solder paste application on PCBs before component placement. In Neardi's production, it ensures optimal solder paste thickness and placement, preventing defects and enhancing the reliability and quality of embedded boards.

X-ray Detector

An X-ray Detector inspects the internal quality of solder joints and components on PCBs, revealing issues like voids or misalignments. In Neardi's production, it ensures thorough inspection of embedded boards, enhancing product reliability by detecting hidden defects that might affect performance.

Neardi Service

Choose Neardi to get the highest quality products, custom designs, and expert support.

Custom Design

Neardi’s technical team can quickly create prototypes based on your project’s design ideas.

Expert Advice

With rich experience in hardware-related technologies, Neardi technical team will give you suggestions based on your project needs and reduce your product costs while ensuring product function realization and quality.

Sample First

After the project starts, we will produce a batch of samples for you first, and after acceptance, we will start mass production.

Technical Support

No need to worry about the progress of subsequent projects, Neardi’s professional technical after-sales team will solve your problems 24 hours a day.